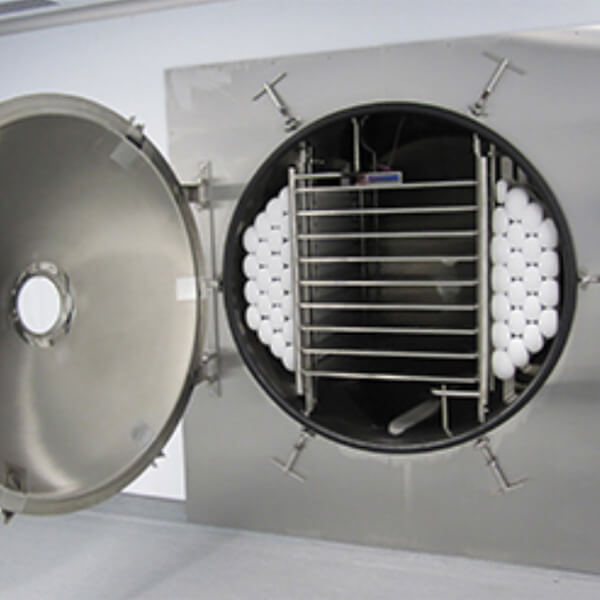

Working Principle

It is to quickly freeze the liquid in the material into solid ice, and directly vaporize the water from the solid-state under the premise of insolubilization of the ice, and continuously remove the vapor, so as to achieve the purpose of drying the material.

Traditional drying can cause the material to shrink, destroying cells. The structure of the sample is not destroyed during freeze-drying because the solid components are supported by the solid ice in their place. As ice sublimates, it leaves pores in the dry leftover material. This preserves the integrity of the product’s biological and chemical structure and its activity.

Applications

- Food industry: vacuum freeze-drying technology can be used for drying fruits and vegetables, meat and poultry, aquatic products, condiments, instant foods and famous and high-quality specialty products, etc. The water is good, the finished product is easy to store and transport, the cost is reduced, and the shelf life is prolonged.

- Nutrition and health care: The vacuum freeze-drying process is used in drying nutritional and health care products such as royal jelly, ginseng, turtles, turtles, and earthworms, which makes people believe that the nutritional products are pure and natural.

- Pharmaceutical industry: The vacuum freeze-drying method can be applied to the dehydration and preservation of Chinese and Western medicines such as serum, plasma, vaccines, enzymes, antibiotics, hormones, etc.

- Biological research: Long-term preservation of blood, bacteria, arteries, bones, skin, cornea, nerve tissue and various organs using vacuum freeze-drying technology can be regenerated only by supplying water during use and still maintain their biophysical properties.

- Others: For example, it can be used in aerospace insulation ceramic production, preservation of wood and silk products in archaeology, specimen production, special material preparation, etc., and can receive unique effects.