Classification by Spray Method

Spray dryer is a one-step direct drying method from raw material solution to finished powder.

Our Spary Dryer Projects

1. Pressure Spray Drying System for SHAMROCK

Through the introduction of one of our German customers, we got to know SHAMROCK TECHNOLOGY in the United States based in Newark, New Jersey, and is renowned for its innovative approach to micronized wax and PTFE micro powder production.

During our initial discussions, Shamrock conveyed their need for a more efficient production process, particularly in the cooling granulation of micronized wax.

Specifically, they were facing the following pain points:

- Low production yield: The existing process was not producing enough output to meet increasing demand.

- Inconsistent particle size: The granulation process was failing to achieve the desired granule size, affecting product quality and performance.

To tackle these challenges, our team engaged in in-depth discussions and experiments in collaboration with leading industry experts from Germany. This collaborative effort allowed us to design a state-of-the-art pressure spray drying system tailored specifically to Shamrock’s requirements.

After the new system was implemented, Shamrock saw remarkable improvements in their production process. The equipment successfully produced micronized wax with the required particle size and significantly increased their yield, ultimately enhancing their operational efficiency.

2. Centrifugal Spray Drying System for KORUMA

We are honored to collaborate with KORUMA KLOR ALKALI SAN.VE TIC.AS., one of Turkey's largest private chemical factories, to provide them with efficient spray drying equipment to assist in their production of copper sulfate.

In our discussions with KORUMA, we learned that they urgently required a high-efficiency centrifugal spray drying solution to meet their increasing production demands. KORUMA encountered several key issues in their existing production process.

- First, the equipment experienced wall stickiness during operation, leading to decreased efficiency, frequent downtimes, and increased operational costs.

- Furthermore, the product absorbed moisture during the drying process, negatively impacting the quality of the final product.

To address KORUMA's specific needs and pain points, our team designed a centrifugal spray dryer with a capacity of 1.5 tons per hour of evaporation. This equipment utilizes advanced technology optimized specifically for wall stickiness and moisture absorption issues:

- Efficient spray system: Optimized nozzle design achieves uniform atomization.

- Unique drying chamber structure: Improves airflow distribution.

- Intelligent control system: Monitors and adjusts temperature and humidity in real-time, ensuring product consistency and quality.

After a period of trial operation, KORUMA expressed high satisfaction with the performance of the new equipment.

Spray Dryers Comparison

When comparing spray dryers, some of the factors that should be considered include: material characteristics, capacity, energy efficiency and cost.

- The power consumption of the centrifugal spray dryer is between pressure and closed loop spray dryers. It is suitable for high-viscosity or liquid with solids, the output can be adjusted within +25% of the designed capacity without affecting product viscosity. It occupies a smaller area, has a larger capacity, and is more convenient to maintain. Its disadvantages are high manufacturing costs, thicker droplets, and larger nozzles, so the diameter of the spray dryer tower is correspondingly much larger than that of the other two spray dryers.

- The power consumption of the pressure spray dryer is the lowest (about 4-10kw/h). It is suitable for the feed liquid of general viscosity. The disadvantage is that it must have a high-pressure pump, the nozzle is small and easy to clog, and the production adjustment range is narrow. In addition, the pressure spray dryer is much higher, so the construction cost will be higher.

- The power consumption of the airflow spray dryer, is the largest, and about 0.4-0.8 kg of compressed air is needed for each kg of feed liquid. However, its structure is simple and easy to manufacture, and it is suitable for any viscosity or slightly solid feed liquid.

For more details, please check the comparison chart below.

Items | Centrifugal Spray Dryer | Pressure Spray Dryer | Air Flow Spray Dryer | |

Material Characteristics | Capacity Adjustment Range | Wide | Narrow | Medium |

High-Viscosity | ✓ | ✕ | ✕ | |

Feeding System | Pressure | Low Pressure, About 3kgf/cm2 | High Pressure, 10~200kgf/cm2 | Low Pressure, About 3kgf/cm2 |

Need High-Pressure Pump? | ✕ | ✓ | ✕ | |

Atomizer | Maintenance | The high-speed rotating device is high precision and difficult to maintenance | The nozzle is easy to wear, and the high pressure pump needs maintenance | Easy |

Power Consumption | Medium | Low | High | |

Final Products | Granularity | Fine-grained | Coarse-grained | Coarse-grained |

Uniformity | ✓ | Roughly | ✕ | |

Bulk Density | Light, the pores of the particles are spherical | Heavy, less air content in the particles | N/A | |

Drying Tower | Hot Air Flow Directions | Countercurrent | Cocurrent, Countercurrent and Mixed | Cocurrent and Countercurrent |

Tower Diameter | Large | Small | Small | |

Tower Height | Low | High | Medium | |

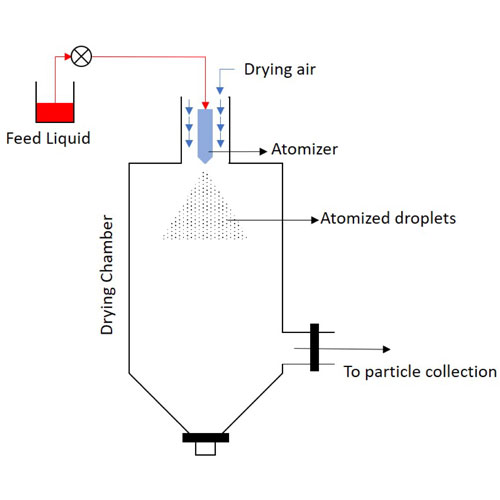

The Parts of Spray Dryers

For different materials or requirements, the spray drying machine systems we design are also different, but these following 5 main basic units are indispensable.

- Feeding system - Depending on the form of the atomizer used and the nature of the material, the feeding method is also different. Commonly used feeding pumps include screw pumps, metering pumps, and diaphragm pumps.

- Heating system - The most important factor in the selection of the heating system is the characteristics of the liquid material. The heating equipment mainly has two types: direct heat supply and indirect heat exchange.

- Atomization system - The atomization system is the core of the entire spray drying system. There are three common types: Centrifugal type - the centrifugal force generated by the high-speed rotation of the machine is the main atomization power; Pressure type - the high pressure generated by the feeding pump is the main atomization power; Air flow type - the kinetic energy generated by the airflow is the main atomization power.

- Drying system - The type of the dryer depends to some extent on the atomizer. It is also a major part of the spray drying design.

- Gas-solid separation system - After the droplets are dried to remove most of the water, they form powder particles, some of which are separated from the gas at the bottom of the drying tower and discharged, and the other part enters the gas-solid separation system with the tail gas and needs to be further separated. There are mainly two types of gas-solid separation: dry separation and wet separation.

Atomizer Selection Criteria

Atomizers are used to break down liquids into small droplets or mist. When selecting an atomizer, there are several criteria to consider.

Items | Centrifugal Atomizer | Pressure Atomizer | Air Flow Atomizer | |

Dryer Tower | Cocurrent | ✓ | ✓ | ✓ |

Countercurrent | ✕ | ✓ | ✓ | |

Mixed | ✕ | ✓ | ✓ | |

Liquid Properties | Low Viscosity | ✓ | ✓ | ✓ |

High Viscosity | ✓ | ✕ | ✓ | |

Non-abrasive | ✓ | ✓ | ✓ | |

General Abrasive | ✓ | ✓ | ✓ | |

High Abrasive | ✓ | ✕ | ✕ | |

Paste (Pumpable) | ✓ | ✓ | ✓ | |

Feeding Speed | ≤3 m3/h | ✓ | ✓ | ✓ |

>3m 3/h | ✓ | Conditional | Conditional | |

Droplet Size | 30~120 μm (400~115 mesh) | ✓ | ✕ | ✓ |

120~250 μm(115~60 mesh) | ✕ | ✓ | ✕ | |

Spray Dryer Applications

Spray Drying in Food Industry

Spray drying is a widely used process in the food industry to produce powders from liquids, including dairy product powder (such as milk and whey), coffee and tea extracts, fruit and vegetable powders, vitamins, starches, carbohydrates, flavors and seasonings.

Spray Drying in Pharmaceutical Industry

Spray drying is particularly useful in the pharmaceutical industry as it enables the production of consistent powders with controlled particle size and morphology. These powders are ideal for the formulation of inhalation products, oral solid dosage forms, and topical formulations.

Spray Drying in Ceramic Industry

Spray drying is an efficient method for producing ceramic powders, as it allows for the production of uniform particles with precise control over particle size and shape. This is particularly important in the production of advanced ceramics, which require high levels of purity and uniformity.