Vibrating Fluidized Bed Dryer

In this type of continuous dryer, a bed of solid particles is fluidized by air and the particles are kept in a state of constant agitation by a vibrating motion which enhanced the fluidization of the particles, promoting better heat and mass transfer, resulting in faster drying.

It is suitable for large-scale production processes that require consistent and efficient drying of bulk materials.

Spin Flash Dryer

In a spin flash dryer, the rotor generates centrifugal force that flings the material against the walls of the chamber, creating a thin film that is exposed to the hot air flowing through the dryer. The hot air evaporates the moisture from the material, and the dry product is collected at the bottom of the chamber.

It is commonly used in the food, chemical, and pharmaceutical industries for applications such as drying starch, gelatin, and other hydrocolloids.

Spray Dryers

We provide centrifugal spray dryers, closed loop spray dryers and pressure spray dryers, they are all continuous type dryers that are commonly used in industrial settings for drying liquids into powders or granules.

Our centrifugal spray dryer adopts a high-speed centrifugal disc atomization method. By atomizing the material into mist droplets, then contact with the hot air distributed in the tower body to form a uniform powdery dry product.

Because the surface area of the atomized material is greatly increased, the drying speed is faster, and the dried product has good quality, high uniformity, and good solubility.

The dried product does not need to be crushed and classified, which reduces the production process. Therefore, it is widely used in drying materials in food, chemical, agricultural, and pharmaceutical industries, especially for drying heat-sensitive materials.

Our explosion-proof closed-loop spray dryer system works in a closed environment, using nitrogen as the circulating gas, and there is no leakage under the pressure of 0.3 MPa.

Its structure is mainly composed of spray dryer, nitrogen closed-circuit circulation system, steam heater, gas-solid separator, nitrogen backflush dust collector, and condensing cooling solvent recovery system.

It is suitable for drying materials with organic solvents, materials with toxic gases, or materials that are prone to oxidation during the drying process.

Our pressure spray dryer is a drying equipment integrating drying and granulation. It is easy to operate and control.

Its working process is to feed the liquid material into the pressure atomizer through a high pressure of 2-20MPa and atomize it into small droplets. The surface area of the atomized droplets is greatly increased, and they can fully contact with the hot air. The drying process is quickly completed within 30 seconds.

The dried product is spherical particles with uniform particle size, high purity and strong adaptability to materials. Therefore, most materials in food, chemical, pharmaceutical, agricultural, ceramic and other industries can be dried by our pressure spray dryer.

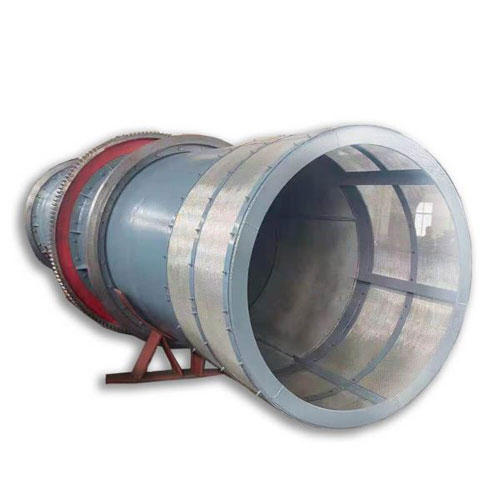

Rotary Kiln Dryer

The rotary kiln is a cylindrical shell that is inclined slightly from the horizontal and rotates slowly about its axis. As the material is fed into the rotary kiln dryer at one end, it moves gradually towards the other end due to the kiln's rotation.

It is commonly used in the processing of bulk solids, such as minerals, chemicals, and agricultural products. It is also used in the production of cement, lime, and other building materials, as well as in the recycling of waste materials.

Mesh Belt Dryer

This type of dryer typically uses a stainless steel conveyor belt to continuously transport and dry materials. It can handle a large volume of materials, making it an efficient and cost-effective solution for industrial drying.

It is commonly used for drying food products, such as fruits and vegetables, as well as chemicals, plastics, and other industrial materials.

Vacuum Belt Dryer

The dryer's conveyor belt (made of a permeable material) moves continuously through a vacuum environment which allows for low-temperature drying, which can help preserve the quality.

It is particularly suitable for drying heat-sensitive materials that cannot be exposed to high temperatures or for drying materials that are easily oxidized or combustible.

Disc Dryer

Our vertical disc dryer consists of a series of rotating discs that are arranged in a stack. When the material is fed onto the top disc, and as the discs rotate, the material moved down and is dried by the heated air inside the chamber. The dried material is finally discharged from the bottom of the dryer.

It is commonly used in chemical, food processing, pharmaceutical, and other industries to dry and process a wide range of materials, including powders, granules, crystals, and other solids.

Air Flow Dryer

This is a type of continuous dryer to remove moisture by passing them through a heated airflow. It can be operated at different temperatures and airflow rates.

It is capable of handling high volumes of material and can produce uniformly dried products with minimal operator intervention. It is commonly used in industries such as agriculture, food processing, and mineral processing to dry products like grains, vegetables, fruits, and minerals.

Contact Us

Get in touch with us now. Our team is ready to help you find the right continuous dryer for your drying project.