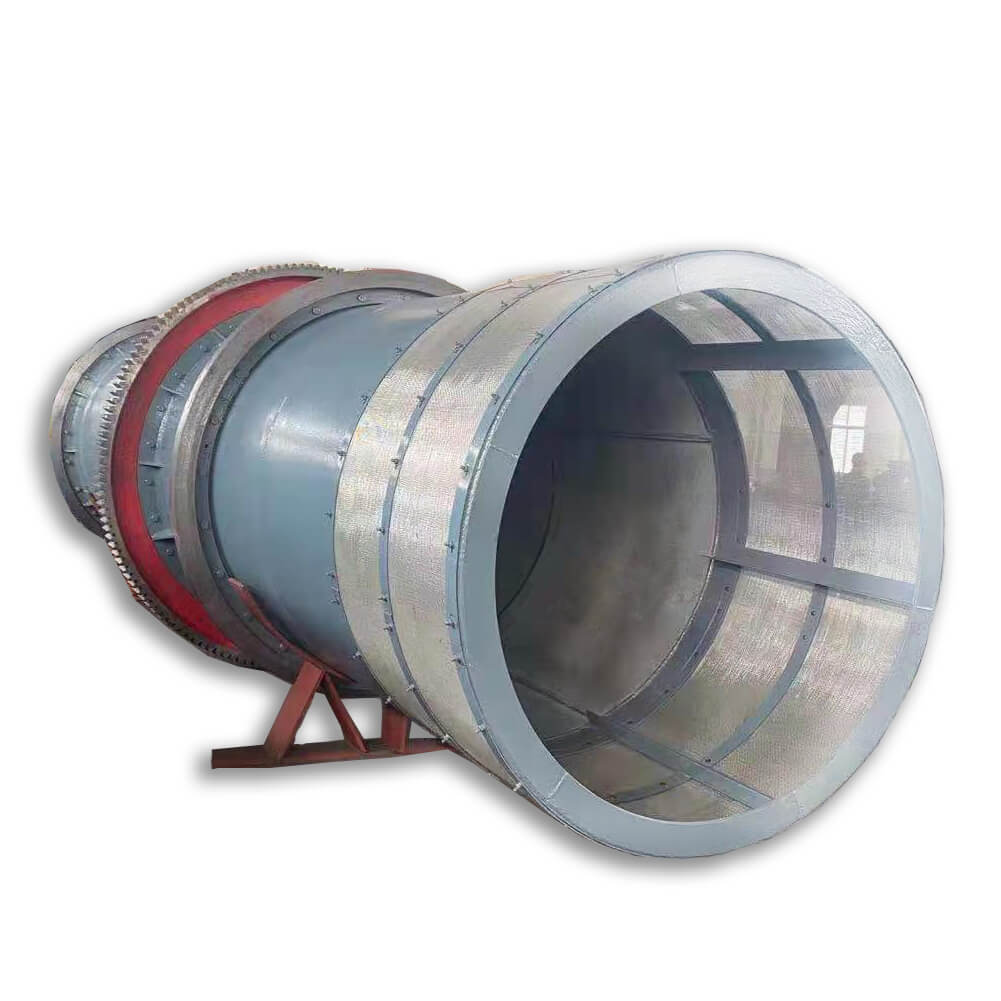

Rotary kiln dryer is a kind of dryer that handles a large amount of materials. It is widely used in metallurgy, building materials, light industry and other industries because of its reliable operation, flexible operation, strong adaptability, and large processing capacity.

Rotary kiln dryers can be applied to granular materials, but also can be used to dry viscous paste materials or materials with high moisture content by mixing with dry materials. The moisture content of the material is generally 3-25%, up to 50%, and the moisture content of the product can reach 0.5%.

Griffin Technology has improved and optimized the design of the rotary kiln dryer on the basis of absorbing advanced technology at home and abroad, which can heat or cool the paste, granular, powder and slurry materials, and can complete the operation of drying, cooling, reaction and calcination. The special mixing, crushing and excitation devices make the equipment have high heat transfer efficiency and self-cleaning function.

Material’s Flow Direction Selection

1. Concurrent flow: the material moves in the same direction as the heat-carrying fluid flow. It is suitable for the following materials.

- The material moisture content is large, and fast drying without cracking and coking.

- After drying, the material cannot resist high temperatures.

- The moisture absorption of the dried material is very small.

2. Counter-current: the direction of material movement is opposite to the direction of heat-carrying fluid flow. It is suitable for the following materials.

- The material moisture content is large, and does not allow rapid drying, so as not to cause the material to crack.

- The dried material can be resistant to high temperatures.

- The dried material has large moisture absorption.

- Requires large drying speed, but at the same time requires low moisture content of the product.

Selection of Heat-carrying Fluid

If the solid material to be dried is not afraid of high temperature and is not the final product, and the intermediate process can be allowed to be slightly contaminated, flue gas can be used as the heat-carrying fluid, and a higher volumetric evaporation rate and thermal efficiency can be obtained. Such as ore, gravel, coal and calcium superphosphate, and other materials with flue gas, the fuel can be coal, oil or natural gas, etc.

If the material to be dried is not allowed to be contaminated, the air is used as the heat carrier fluid. Hot air can be obtained by steam heat exchangers or indirectly heated hot air furnaces.

Wood Chips Drying Solutions

Customer's Material & Related Parameters | |

Material | Wood Chips |

Capacity Requirement | 5000kg/h |

Initial Moisture | 50% (wet basis) |

Final Moisture | 12% (wet base) |

Heat Source | Direct-fired hot air furnace |

Dust Removal System | Bag dust collector |

Equipment Material | Q235 Steel |

Power Supply | 380V 50HZ |

Environment | 15℃, 760mmHg, φ=80% |

Rotary Kiln Dryer Configuration List | ||||

ID | Equipment Name | Models & Specifications | Material | Quantity |

1. Infeed & Outfeed System | ||||

1 | Wet Material Transition Bin | Q235 Steel | 1 | |

2 | Feeding Screw | Φ400, 11KW | 1 | |

3 | Discharge Shut-off Fan | Φ300, 4KW | 1 | |

2. Heating System | ||||

1 | Coal-fired Hot Air Furnace | 3 million calories | 1 | |

2 | Insulation Layer | Rockwool | ||

3 | Equipment support | A3 Steel | 1 | |

3. Drying System | ||||

1 | Rotary Kiln Dryer | HZG-φ3×14 | Q235 Steel | 1 |

2 | Kiln Head | DN3250 | Q235 Steel | 1 |

3 | Kiln Tail | DN3250 | Q235 Steel | 1 |

4 | Feeding Port | Φ400 | Q235 Steel | 1 |

5 | Discharge Port | Q235 Steel | 1 | |

6 | Hot Air Inlet | Φ1000 | Q235 Steel | 3 |

7 | Exhaust Gas Outlet | Φ950 | Q235 Steel | 1 |

8 | Large Gear Ring | ZG | 1 | |

9 | Pinion Gear | ZG | 1 | |

10 | Drive Motor | 37KW | Variable frequency control | 1 |

11 | Hard Gear Reducer | 1 | ||

12 | Pinion Gear, Drive Seat | Q235 Steel | 1 | |

13 | Large Rolling Ring | ZG | 2 | |

14 | Small Rollers | ZG | 4 | |

15 | Retaining Wheel | Φ300 | ZG | 2 |

16 | Roller Cover | Q235 Steel | 1 | |

17 | Integral Base | Q235 Steel | 1 | |

4. Dust Removal System | ||||

1 | Exhaust Air Duct | Φ1000 | Q235 Steel | 1 |

2 | Bag Filter | MC-3-- | Q235 Steel | 1 |

3 | Induced Draft Fan | 170KW | A3 Steel | 1 |

5. Control System | ||||

1 | Control Cabinet | Standard control cabinet | Carbon steel spraying | 1 |

2 | Electrical Component | Matching set | Siemens | 1 |

3 | Inverter | Matching set | Siemens | 1 |