Optimization

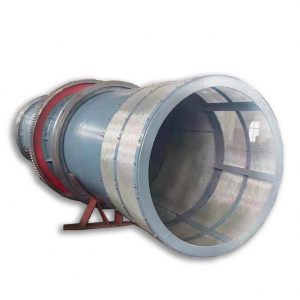

Griffin Technology has been continuously optimizing the airflow dryer.

The airflow dryer is mainly used in the drying of starch and the drying of some inorganic salt products, such as drying of sodium sulfate and sodium metabisulfite, which has always had its unique advantages.

In the feeding mechanism of the air dryer, We have designed a unique anti-arch device, which can ensure the smooth and smooth entry of the raw materials into the air stream dryer without the phenomenon of bridging.

In the main engine of the airflow dryer, a unique pulse link is designed. Some products have relatively high requirements for final moisture. In order to prolong the drying time in the airflow dryer, we have made a pulse expansion section, which will buffer the drying of the product. The speed makes more full contact with the hot air.

In the dust removal and collection process of the airflow dryer, considering a large amount of dust, we have made explosion venting devices in the bag filter and the host to achieve the purpose of safe production.

Actual Measurement Data of Material Suspension Speed

Raw Material Name | True Density (kg/m3) | Bulk Density (kg/m3) | Particle Size (mm) | Suspension Speed (m/s) |

Wheat | 1270~1490 | 650~810 | 4~4.5 | 9.8~11 |

Barley | 1230~1300 | 600~700 | 3.5~4.2 | 8.7~10.5 |

Paddy | 1020 | 550 | 3.58 | 7.5 |

Rice | 1480 | 620~680 | 10×3 | 8~8.5 |

Corn | 1240~1350 | 600~620 | 9×8×6 | 9.8~13.5 |

Soybean | 1180~1220 | 560~720 | 3.5~10 | 10 |

Rapeseed | 1040 | 640 | 1.3~2.2 | 7.6~8.8 |

Granulated Sugar | 1580 | 720~880 | 0.51~1.5 | 8.7~12 |

Dry Fine Salt | 2200 | 900~1300 | <1.0 | 9.8 |

Coarse Salt | 1090 | 720 | 7~7.2 | 14.8~15.5 |

Flour | 1410 | 610 | 0.163~0.197 | 1.5~2 |

Washing Powder | 1270 | 480 | <0.5 | 2 |

Soda | 2480 | 530 | <0.12 | 2.5 |

Talcum Powder | 2600~2850 | 560~950 | >0.01 | 0.5~0.8 |

Clay | 2200~2600 | 320~490 | N/A | 1.8~2.1 |

Zincite | 4300 | 2280 | N/A | 17.7 |

4% Moisture Content Dry Sand | 2300~2600 | 1410 | 50~100 Mesh | 5.13~5.53 |

Molding Sand | 2400 | 1020 | 50~100 Mesh | 8.1~10 |

Ammonium Sulfate | 1770 | 995 | 1.5 | 10.1~13.1 |

Phosphate Rock Powder | 2580 | 1467 | <3.2 | 4.1~11.2 |

Polypropylene Pellets | 900 | 460 | 2~3 | 6.2~6.9 |

Coal | 1000~1700 | 720~940 | 1~3 | 4~5.3 |

Coal | 1000~1700 | 720~940 | 3~5 | 4.2~6.8 |

Coal | 1000~1700 | 720~940 | 5~7 | 6~10.2 |

Coal | 1000~1700 | 720~940 | 10~15 | 11~13.3 |

Potato Starch Airflow Drying Solution

Customer's Material & Related Parameters | |

Material | Potato Starch |

Capacity Requirement | ≧100kg/h |

Initial Moisture | 60% (wet basis) |

Final Moisture | ≤10% (dry basis) |

Raw Material Specific Gravity | Stacking specific gravity 0.7 |

Feed Temperature | Normal temperature |

Discharge Temperature | 50℃ |

Heat Source | Natural gas hot air furnace |

Equipment Process Conditions | |

Receiving Method | Cyclone + bag dust collector |

Air Flow Dryer Model | QG-350 *1 |

Feeding Method | Screw conveyor |

Hot Air Contact Mode | Parallel flow |

Inlet Air Temperature | 160℃ |

Outlet Air Temperature | 60℃ |

Material Requirements | Product contact 304 stainless steel |

Dust Removal Method | Cyclone + bag dust collector |

Installation Site | Indoor |

Installation Site Size | Plant condition drawing is required |

Noise | <80 db |

Public Works Conditions | |

Atmospheric Pressure | 101.3KPa |

Ambient Temperature | 10℃ |

Relative Humidity | 70% |

Electric Power | 380V, 3 phase, 50HZ |

Machine Power | 30KW/unit |

Compressed Air Consumption | 1.1m³/min |

Compressed Air Pressure | 0.3~0.6mpa |

Air Flow Dryer Configuration List | ||||

ID | Name | Models & Specifications | Material | Quantity |

1. Feeding System | ||||

1 | Screw Feeder | LJ-108 | SUS304 | 1 |

2 | Feeding Pipeline | 108 Casing Spiral | SUS304 | 1 |

3 | Arch Breaker System | 18mm round steel | SUS304 | 1 |

2. Drying medium circulation system | ||||

1 | Air Blower | 4-72-4.5A | Q235 | 1 |

2 | Induced Draft Fan | 9-26-6.3A | Q235 | 1 |

3 | Hot Air Duct | Inner δ=2mm | SUS304 | 1 |

4 | Powder Discharge Air Duct | δ=3mm | SUS304 | 1 |

5 | Pipe Connection | Flange type | Q235 | 1 |

3. Air Heating & Purification System | ||||

1 | Ⅰ & Ⅱ Efficiency Air Filter | 2000X1500X500 | Q236 | 1 |

2 | Direct-fired Gas-fired Hot Air Furnace | 13X104kcal | 301S | 1 |

4. Drying System | ||||

1 | Main Pipeline | D290mm | SUS304 | 1 |

2 | Pulse Tube | D380mm | SUS304 | 1 |

3 | Main Machine Skeleton | Q235+SUS304 | 1 | |

5. Material Collection System | ||||

1 | One-stage Cyclone Separator | XF750, straight section δ=4mm, Tapered section δ=3mm | SUS304 | 1 |

2 | Air Hammer | SK-60 | Cast aluminum | 2 |

3 | Continuous Discharge Valve | 8L | SUS304 | 1 |

4 | Bag dust collector | MCBD-64 | SUS304 | 1 |

5 | Solenoid Valve | 8 | ||

6. Control System | ||||

1 | Control Cabinet | Carbon steel spraying | 1 | |

2 | Temperature Module | Siemens | 1 | |

3 | Contactor Components | Siemens | 1 | |

4 | Inverter | Siemens | 2 | |