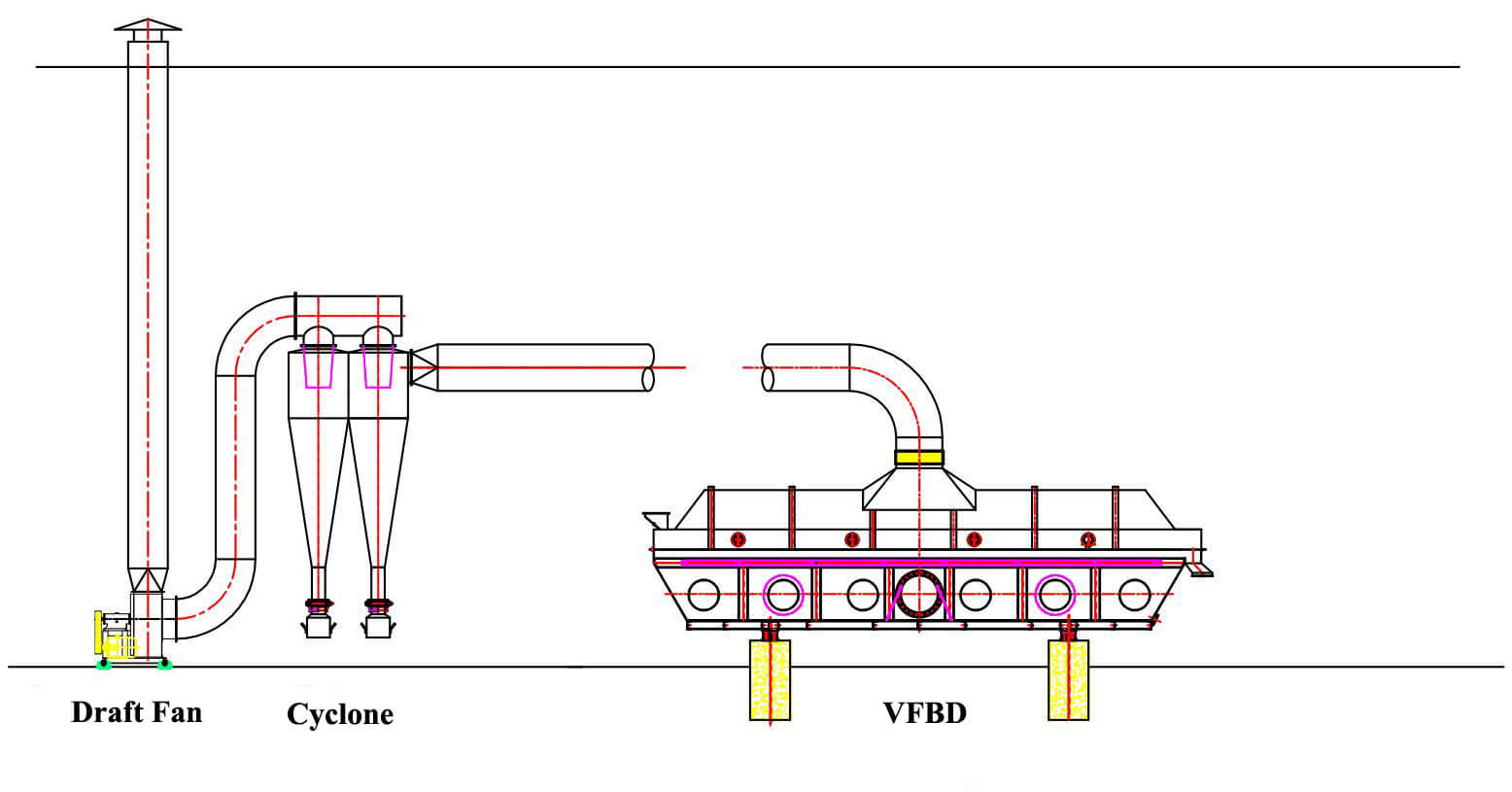

Vibrating Fluid Bed Dryer Flow Chart

Technical Parameters

|

Model |

Fluidized bed area (m2) |

Inlet air temperature (℃) |

Outlet air temperature (℃) |

Dry strength (kg.H2O/h) |

Vibration motor |

|

|

Model |

power |

|||||

|

ZLG3×0.3 |

0.9 |

70-140 |

40-70 |

30-45 |

ZDS31-6 |

0.8×2 |

|

ZLG4.5×0.3 |

1.35 |

70-140 |

40-70 |

45-75 |

ZDS31-6 |

0.8×2 |

|

ZLG4.5×0.45 |

2.025 |

70-140 |

40-70 |

70-125 |

ZDS32-6 |

1.1×2 |

|

ZLG4.5×0.6 |

2.7 |

70-140 |

40-70 |

90-150 |

ZDS41-6 |

1.5×2 |

|

ZLG6×0.45 |

2.7 |

70-140 |

40-70 |

90-150 |

ZDS32-6 |

1.1×2 |

|

ZLG6×0.6 |

3.6 |

70-140 |

40-70 |

120-200 |

ZDS41-6 |

1.5×2 |

|

ZLG6×0.75 |

4.5 |

70-140 |

40-70 |

150-250 |

ZDS42-6 |

2.2×2 |

|

ZLG6×0.8 |

4.8 |

70-140 |

40-70 |

160-270 |

ZDS42-6 |

2.2×2 |

|

ZLG6×0.9 |

5.4 |

70-140 |

40-70 |

180-300 |

ZDS42-6 |

2.2×2 |

|

ZLG7.5×0.6 |

4.5 |

70-140 |

40-70 |

150-250 |

ZDS42-6 |

2.2×2 |

|

ZLG7.5×0.75 |

5.625 |

70-140 |

40-70 |

190-315 |

ZDS51-6 |

3.0×2 |

|

ZLG7.5×0.8 |

6 |

70-140 |

40-70 |

200-335 |

ZDS51-6 |

3.0×2 |

|

ZLG7.5×0.9 |

6.75 |

70-140 |

40-70 |

225-375 |

ZDS51-6 |

3.0×2 |

|

ZLG7.5×1.2 |

9 |

70-140 |

40-70 |

300-500 |

ZDS51-6 |

3.0×2 |

|

ZLG7.5×1.5 |

11.25 |

70-140 |

40-70 |

375-625 |

ZDS51-6 |

4.0×2 |

|

ZLG8×1.2 |

9.6 |

70-140 |

40-70 |

320-535 |

ZDS51-6 |

4.0×2 |

|

ZLG8×1.5 |

12 |

70-140 |

40-70 |

400-670 |

ZDS51-6 |

5.5×2 |

|

ZLG8×1.8 |

14.4 |

70-140 |

40-70 |

480-800 |

ZDS51-6 |

5.5×2 |

1. Hot Air System

This system provides clean air before drying.

- Filtration capacity: 8000m3/h (max)

- Pressure drop: 50Pa

- Material: filter material is non-woven fabric

- Heating system: direct-fired gas hot blast stove

- Heater material: inner tank 310S stainless steel

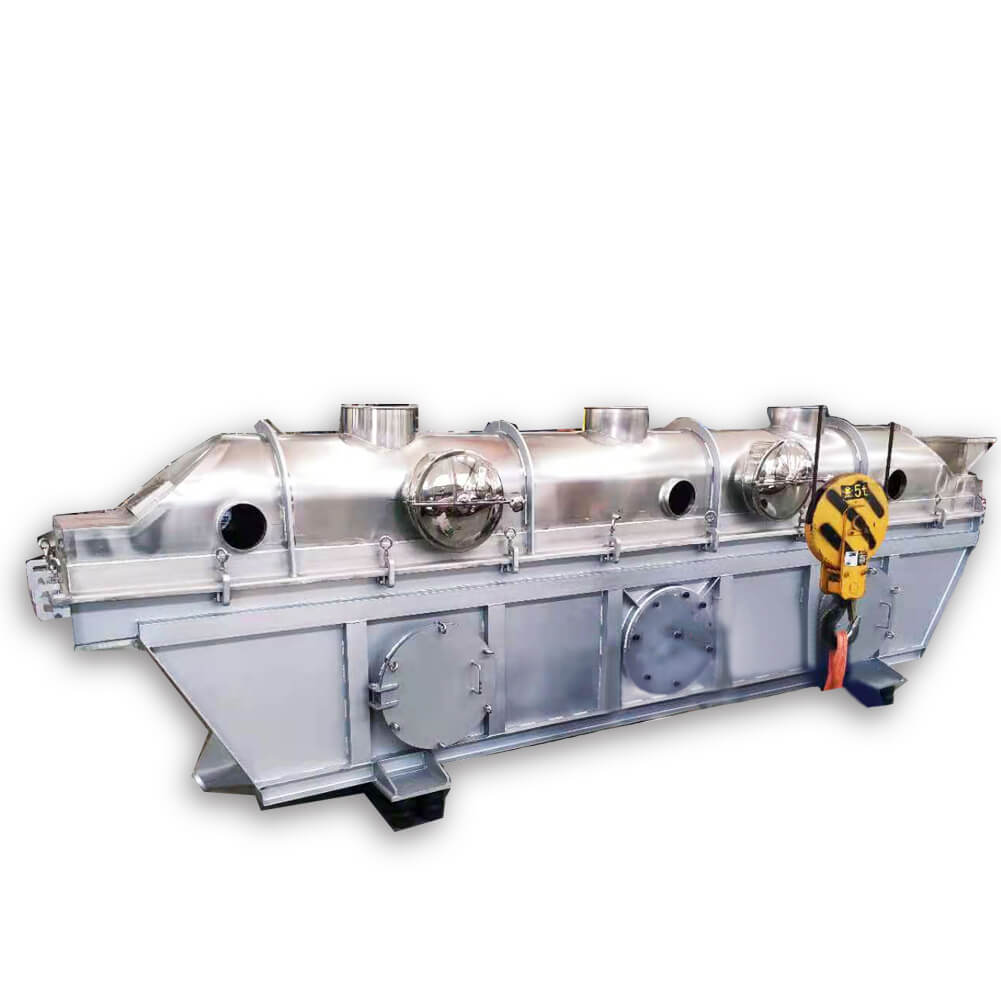

2. Drying System

Upper Bed Body: The upper bed separates the drying area from the atmosphere to prevent dust leakage from causing environmental pollution. The size of the upper part is larger than that of the lower part, so the wind speed of the upper part is lower than that of the lower part, which is conducive to particle sedimentation, reduces the amount of dust entrained, and reduces the amount of dust collected by the dust collector. The amount of dust, less dust is emitted to the atmosphere, and it is more environmentally friendly

Lower Bed Body: The lower bed is the air chamber into which the hot air enters, and the bed board completes the task of evenly sending the hot air into the bed. At the same time, the vibration motor is also installed on the lower bed. The volume of the lower bed is related to the uniformity of the pressure drop and the fluctuation of the pressure drop. For this reason, there must be a large enough volume and length of the lower bed, we can provide 30 vibrating fluid bed, 40 vibrating fluid bed, and 60 feet long vibrating fluid bed. The lower bed must bear the dynamic load of all the vibration bodies, so The lower bed should be designed as a box frame structure.

Bed Board: The main machine adopts the combined opening method of the serpentine hole and straight hole. The material contact adopts SUS316L stainless steel.

3. Dust Removal System

This system is composed of one set of SUS304 stainless steel primary cyclone separator, its diameter is XF-φ900.

4. Control System

Electrical control system configuration description:

- The inlet air temperature is automatically adjusted by PLC.

- The feeding amount can be automatically adjusted according to the change of the outlet air temperature.

- Real-time monitoring of the main parameters such as the pressure in the dryer, the temperature of the air inlet and outlet, and the differential pressure.

ZLG 6×0.6 Vibrating Fluid Bed Drying Solution for NaCl

1. Material Properties | |||

Material Name | NaCl | Specific Gravity of Raw Material | 2.165kg/cm³ |

Moisture State | Free Water | Feeding Temperature | Normal Temperature |

Capacity | 1,000kg | Discharge Temperature | <50℃ |

Wet Basis Moisture Content | 6% | Heat Source | Natural Gas Hot Blast Stove |

Dry Basis Moisture Content | ≤1 | Dust Removal Method | Cyclone Dust Collector |

2. Equipment Process Conditions | |||

Equipment Model | ZLG 6X0.6 Vibrating Fluidized Bed | Dust Removal Method | Cyclone dust collector |

Feeding Method | Centrifuge Vertical Feeding | Installation Site | Indoor |

Hot Air Contact Method | Parallel Flow | Device layout | Plant drawing is required |

Inlet Air Temperature | About 150℃ | Noise | <80 dB |

Outlet Air Temperature | 70~80℃, Discharge Temperature 30℃ | The Number of Equipment | 1 Set |

Material Requirements | 316L (contact with the material) | Lead Time | 60 Days |

3. Public Works Conditions | |||

Atmospheric Pressure | 101.3KPa | Power | 380V, 3-phase, 50HZ |

Ambient Temperature | 10℃ | Installed Power | About 25KW/Unit |

Relative Humidity | 70% | Compressed Air Consumption & Pressure | 0.6m³/min & 0.3mpa |

ZLG 9×1.0 Vibrating Fluid Bed Drying Solution for Sodium Gluconate

1. The Process Conditions | |

Material | Sodium gluconate |

Water State | Free water |

Output | 5000kg/h |

Wet Base Moisture Content | 5% (Free water) |

Dry Base Moisture Content | <0.5%(Free water) |

Rated Evaporation Capacity | 350kg/ h |

True Density of Materials | 2165kg/ m3 |

Material Bulk Density | 1200kg/ m3 |

Feeding Temperature | 20℃ |

Discharging Temperature | 45°C |

Heat Source | Saturated steam |

2. The Main Equipment Requirements | |

Equipment Model | ZLG 9x1.0 *1 |

Dust Removal Method | Cyclone + cloth bag dust collector |

Material Requirements | Q235+316L Steel |

Bed Area | 9.0㎡ |

Installation Site | indoors |

3. The Main Equipment Requirements | |

Intake Air Temperature | 150 °C |

Outlet Air Temperature | 80 °C |

Fluidization Time | 4 mins |

Cooling Temperature | 22°C |

Electric Cabinet Controler | PLC+ touch screen |

Static Material Layer Thickness | 3.5cm |

Bed Plate Opening Rate | 4% |

Area of Steam Heat Exchanger | 400㎡ |

Steam Consumption | 1050kg/ h |