Mesh belt dryers are commonly used in various industries for drying products like food, pharmaceuticals, and chemicals. These dryers work by passing materials over a perforated mesh belt while hot air circulates to remove moisture.

The manufacturing of a mesh belt dryer involves several critical sheet metal fabrication techniques to ensure the dryer operates efficiently and withstands the wear and tear of continuous use.

The most commonly used techniques in mesh belt dryer manufacturing are cutting, bending, welding, and punching.

Below, we will explore which parts of the mesh belt dryer require these techniques.

1. Cutting – Essential for Creating Precise Shapes and Sizes

Cutting is one of the most fundamental steps in the manufacturing process of a mesh belt dryer. It is used to shape the metal sheets into the desired dimensions for various parts of the dryer.

- Dryer Frame: The main structure of the mesh belt dryer is often made of robust metal materials, such as stainless steel or galvanized steel, which provide durability and resistance to high temperatures. Cutting techniques, such as laser cutting, plasma cutting, or shearing, are used to cut the metal sheets to the required lengths and shapes.

- Air Flow Ducts: The ducts through which hot air flows during the drying process are often made from sheet metal. These ducts need to be precisely cut to ensure optimal airflow and efficient drying. The cuts also need to be made at specific angles to allow for proper air circulation.

- Mesh Belt Guards: The protective guards that encase the mesh belt need to be cut to the correct dimensions. These guards protect workers and prevent objects from falling into the drying chamber.

2. Bending – Forming Structural Components

Sheet metal bending is used to shape metal sheets into various forms, such as brackets, edges, and supports. The process involves applying force to the metal sheet to create a specific angle or curve, which is crucial for certain parts of the mesh belt dryer.

- Frame Components: The frame of the dryer is made up of several bent pieces of sheet metal that provide structural integrity. These bent components form the sides, corners, and support structures for the mesh belt and drying chamber. Techniques like air bending or bottom bending are often used to create V-shaped, U-shaped, or L-shaped parts.

- Bracket Supports: Brackets are essential in holding the mesh belt in place and ensuring that the dryer functions as intended. These brackets are made by bending metal sheets to form the necessary angles to support the weight of the belt.

- Ductwork Bends: In the construction of air ducts, bending is used to form smooth curves or right-angle turns. This ensures that air flows through the system without obstruction and maintains the efficiency of the drying process.

3. Welding – Assembling the Structure

Welding is used to join various sheet metal components into a single, solid structure. This technique is essential for ensuring the overall stability and durability of the mesh belt dryer, especially for the larger, load-bearing components.

- Frame Assembly: After cutting and bending, the individual parts of the mesh belt dryer frame need to be welded together to form the overall structure. Welding ensures the frame remains stable and strong enough to support the mesh belt, the material being dried, and the airflow system. TIG welding, MIG welding, and spot welding techniques are commonly employed, with the choice depending on the material and thickness of the metal sheet.

- Airflow System: The air ducts and other components that direct the hot air through the drying chamber are often welded together to ensure airtight seals. Maintaining consistent air pressure and temperature throughout the drying process is crucial for optimal results.

- Mesh Belt Guides: The guides that hold and direct the mesh belt during the drying process are welded onto the frame of the dryer. Welding these parts ensures they stay securely in place, even during high-speed operations.

4. Punching – Creating Holes and Perforations

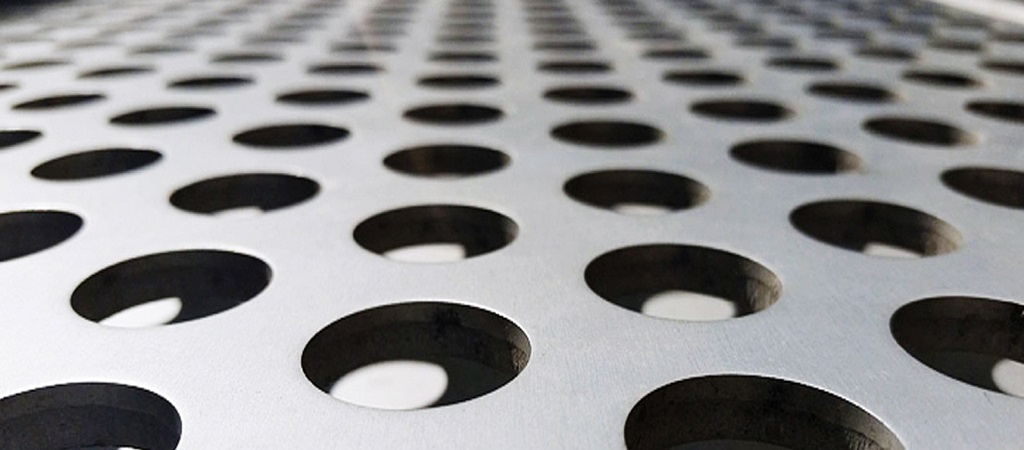

Punching involves using a press to create holes or perforations in sheet metal, which is especially important in the design of the mesh belt dryer. These perforations allow air to circulate more efficiently and help ensure that the dryer functions optimally.

- Mesh Belt: The mesh belt itself is made from metal that is perforated with small holes to allow hot air to pass through while the material is being dried. Custom metal punching is used to create the precise holes in the metal sheet that will form the belt.

- Air Flow Perforations: In addition to the mesh belt, certain parts of the air ducts and chamber walls may need to be perforated with holes to allow for controlled airflow. These perforations help to distribute heat evenly throughout the drying chamber.

- Access Panels: Access panels or inspection covers are often punched with holes to create handles or lock openings. These panels allow maintenance personnel to easily inspect the dryer or adjust the mesh belt as needed.

Conclusion

In the manufacturing of mesh belt dryers, sheet metal fabrication techniques like cutting, bending, welding, and punching play a vital role in ensuring the functionality, efficiency, and durability of the equipment. From the frame structure to the airflow ducts, each component relies on these techniques to be properly shaped, assembled, and fitted.

By utilizing these fabrication methods, manufacturers can produce mesh belt dryers that meet the demanding needs of industries where drying efficiency is critical.