Spray Dryer in Pharmaceutical Industry

Spray drying is a commonly used technique in the pharmaceutical industry for converting liquid drugs into a dry powder form.

The pharmaceutical industry uses spray dryers for a variety of applications, including the production of inhalable dry powders for respiratory drugs, the manufacture of tablets and capsules, and the production of powders for intravenous administration. Spray drying can also be used to produce microencapsulated drugs, which protect the active ingredient from degradation and improve bioavailability.

They are suitable for producing uniform and free-flowing powders, and they are especially suitable for heat-sensitive materials.

Fluidized Bed Dryer in Pharmaceutical Industry

In the pharmaceutical industry, fluidized bed dryers are used to dry a wide range of products, including active pharmaceutical ingredients (APIs), excipients, and other raw materials. They are also used to dry finished products, such as tablets and capsules, before packaging.

Fluidized bed dryers also provide better control over the drying process, as the temperature, humidity, and air flow can be adjusted according to the requirements of the material being dried.

The fluidized bed provides excellent mixing and heat transfer, making it an ideal choice for drying heat-sensitive materials, so it can handle a wide range of materials, from fine powders to granules and pellets.

Tray Dryer in Pharmaceutical Industry

Tray dryers are popular in the pharmaceutical industry because they are relatively simple to operate, require minimal maintenance, and can be used for a wide range of products. They are also flexible, as the temperature and drying time can be adjusted to suit the specific requirements of the product being dried.

In addition, it has ability to dry delicate materials such as antibiotics and other heat-sensitive compounds. The trays in the dryer are designed to minimize damage to the material being dried, ensuring that the final product is of high quality.

Tray dryers are cost-effective and easy to operate, but they are not suitable for large-scale production.

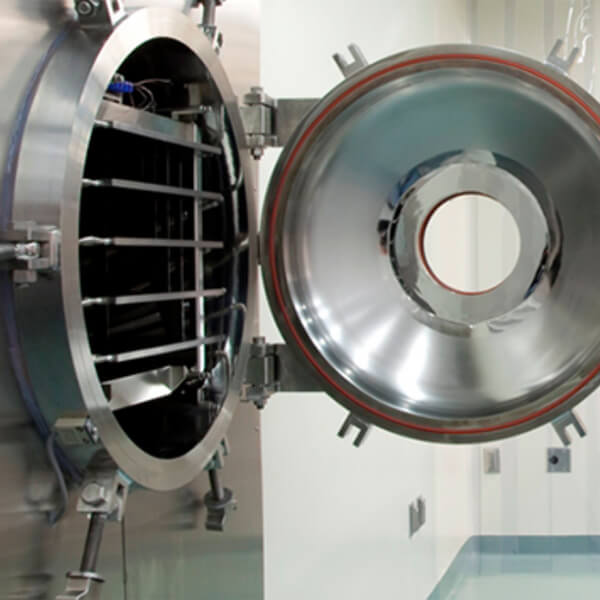

Vacuum Dryer in Pharmaceutical Industry

Vacuum dryers are commonly used in the pharmaceutical industry for the drying of heat-sensitive materials as it minimizes the risk of thermal degradation, such as pharmaceutical powders, granules, and other solid dosage forms.

One of the main advantages of vacuum dryers in the pharmaceutical industry is that they can be designed to prevent cross-contamination between batches. The drying chamber can be isolated from the external environment, ensuring that there is no contamination from the surrounding air or other materials.

Freeze Dryer in Pharmaceutical Industry

Vacuum freeze drying, also known as lyophilization, it is a slow process, but it is ideal for preserving the biological activity of pharmaceutical products, such as vaccines and enzymes.

Vacuum freeze drying is particularly useful for preserving biological materials that are sensitive to heat or moisture, as it can be done at low temperatures, typically below -50°C, and in a low-humidity environment. This helps to maintain the structural integrity and activity of the material.

Contact Us

Get in touch with us now. Our team is ready to help you find the right solution for your pharmaceutical drying project.